Aluminium / Aluminum 1100 Alloy (UNS J91100)

Introduction

Aluminium / Aluminum alloys have strong corrosion resistance. They are sensitive to high temperatures ranging between 200 and 250°C (392 and 482°F) and might lose some of their strength. However, the strength of the aluminum alloys can be increased at subzero temperatures, making them ideal low-temperature alloys.

The aluminum 1100 alloy is a pure aluminum alloy with excellent forming characteristics. The following datasheet will provide more details about Aluminium / Aluminum 1100 alloy.

Chemical Composition

The following table shows the chemical composition of Aluminium / Aluminum 1100 alloy.

| Element | Content (%) |

|---|---|

| Aluminium / Aluminum , Al | 99.00 (min) |

| Copper , Cu | 0.12 |

Physical Properties

The physical properties of Aluminium / Aluminum 1100 alloy are outlined in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 2.71 g/cm3 | 0.0979 lb/in³ |

Mechanical Properties

The mechanical properties of Aluminium / Aluminum 1100 alloy are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

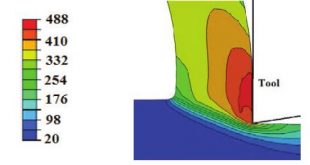

Thermal Properties

The thermal properties of Aluminium / Aluminum 1100 alloy are tabulated below.

| Properties | Conditions | ||

|---|---|---|---|

| T (ºC) | Treatment | ||

| Thermal conductivity | 218 W/mK | 25 | H18 |

| Thermal expansion | 23.6 x 10-6/ºC | 20-100 | – |

Other Designations

Equivalent materials to Aluminium / Aluminum 1100 alloy are as follows.

| AMS 4003 | AMS 7220 | ASTM B209 | ASTM B210 | ASTM B211 | ASTM B221 |

| ASME SFA5.10 (ER1100) | ASME SFA5.3 (E1100) | ASTM B241 | ASTM B247 | ASTM B313 | ASTM B316 |

| ASTM B361 | ASTM B361 | ASTM B479 | ASTM B483 | ASTM B491 | ASTM B547 |

| ASTM B548 | MIL A-52174 | MIL A-52177 | MIL C-26094 | MIL R-5674 | MIL S-24149/5 |

| AWS A5.10 (ER1100) | AWS A5.10 (ER1100) | AWS A5.3 (E1100) | MIL E15597 (MIL-1100) | MIL I-23413 (MIL-1100) | QQ WW-T-700/1 |

| MIL W-6712 | MIL W-85 | QQ A-1876 | QQ A-1876 | QQ A-250/1 | QQ A-430 |

| SAE J454 |

Fabrication and Heat Treatment

Machinability

Aluminium / Aluminum 1100 alloy has excellent machinability especially when the alloy is machined in hard temper. Carbide tooling is suitable, but high speed steel tooling can also be used. In cases where heavy cuts are required, an oil lubricant must be used.

Forming

Both hot and cold forming is easy to perform with Aluminium / Aluminum 1100 alloy. This alloy can be cold worked extensively in the annealed condition without the need for intermediate annealing.

Welding

Welding can be easily performed using all the conventional methods. It is suitable to use AL 1100 consumable electrodes and filler wire for the process.

Heat Treatment

Aluminium / Aluminum 1100 alloy cannot be successfully heat treated other than to produce the annealed form and ‘O’ temper.

Forging

Aluminium / Aluminum 1100 alloy can be hot forged without much difficulty.

Hot Working

Hot working can be easily performed on Aluminium / Aluminum 1100 alloy.

Cold Working

Aluminium / Aluminum 1100 alloy is best suited for cold working as it has good ductility in the annealed temper condition. It can also be cold formed by bending, drawing or spinning.

Annealing

After Aluminium / Aluminum 1100 alloy is extensively cold worked, annealing is required and can be performed at 343°C (650°F) for a suitable amount of time so as to ensure thorough heating and then it can be air cooled.

Hardening

Aluminium / Aluminum 1100 alloy can be hardened by cold working only.

Applications

Aluminium / Aluminum 1100 alloy is widely used in fin stock, heat exchanger fins, spun hollowware, dials and name plates, decorative parts, giftware, cooking utensils, rivets and reflectors, and in sheet metal work.

FOR Finite Element Method 3D design & FEM simulations corporation

FOR Finite Element Method 3D design & FEM simulations corporation